Welcome to our blog post on how to fix a stripped bolt hole in engine block. In this post, we will go over the steps you can take to try and fix the problem before taking your car into a shop. We hope you find this information helpful!

Summary: There are a few steps to take if you have a stripped bolt hole in an engine block. Start by identifying the stripped bolt hole and removing the damaged engine block. Install the new engine block and make a new hole in it. Use a tap to create threads in the new hole, and then screw in a new bolt and tighten it up.

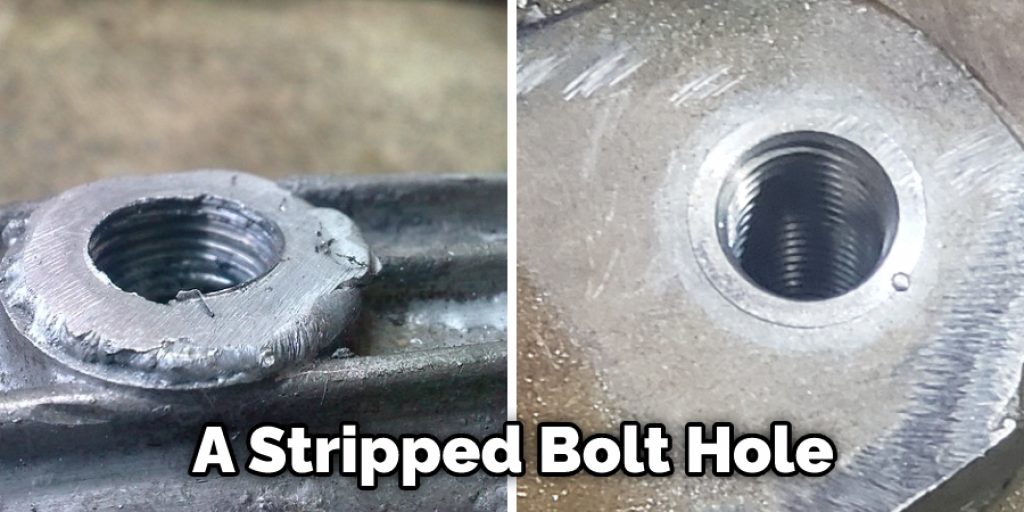

What Is a Stripped Bolt Hole in Engine Block?

A stripped bolt hole is a hole in an engine block that has been damaged by spinning or stripping a bolt. This can occur during the installation or removal of a bolt and can cause serious damage to the engine.

In some cases, a stripped bolt hole may only cause cosmetic damage, but it can cause the engine to leak oil or coolant in others. It can even cause the engine to seize up completely in severe cases.

If you suspect that you have a stripped bolt hole in your engine, it is important to have it repaired as soon as possible by a qualified mechanic.

Why It’s Important to Fix a Stripped Bolt Hole in An Engine Block?

A stripped bolt hole in an engine block may not seem like a big deal, but it can cause serious problems. First of all, it can lead to oil leaks. As the oil seeps out, it will eventually make its way into the combustion chamber, causing the engine to lean. This can lead to premature wear and tear on the engine components and decreased fuel economy.

A stripped bolt hole can also cause coolant leaks. If the coolant mixes with the oil, it can create a sludge that can clog up the oil passages and cause more damage to the engine. Fixing a stripped bolt hole is important because it can help prevent these problems from occurring.

Required Materials

- Engine block repair kit

- Screw extractor set

- Drill

- Tapping set

- Wrench set

How to Fix a Stripped Bolt Hole in Engine Block Step by Step Guide

Step 1: Gather Necessary Materials and Tools

To fix a stripped bolt hole in an engine block, you will need the following materials and tools:

- Thread repair kit (e.g., Heli-Coil or Time-Sert)

- Clean rags

- Brake cleaner or acetone

- Cutting oil or lubricant

- Drill with appropriate drill bit (included in the repair kit)

- Tap wrench

- Thread tap (included in the repair kit)

- Thread insert (included in the repair kit)

- Insertion tool (included in the repair kit)

- Torque wrench

- Safety goggles

- Gloves

Step 2: Choose the Correct Thread Repair Kit

Determine the size and thread type of the bolt hole you need to repair. Select a thread repair kit that matches the bolt size and thread type. Repair kits such as Heli-Coil or Time-Sert are commonly used for this purpose and are available in various sizes and thread types.

Step 3: Prepare the Work Area

Ensure that the engine block and surrounding area are clean and free from dirt, grease, and debris. Use clean rags and a suitable cleaning agent such as brake cleaner or acetone to clean the area.

Step 4: Drill Out the Stripped Bolt Hole

Put on your safety goggles and gloves to protect your eyes and hands during the drilling process. Following the instructions provided in the thread repair kit, drill out the stripped bolt hole using the appropriate drill bit size. Apply cutting oil or lubricant to the drill bit to prevent overheating and ensure a smooth drilling process.

Step 5: Tap the New Thread

Apply cutting oil or lubricant to the thread tap provided in the repair kit. Insert the tap into the drilled hole and attach it to the tap wrench. Slowly and carefully turn the tap wrench clockwise to create a new thread in the hole. Make sure to keep the tap straight and aligned with the hole while tapping. Periodically reverse the tap wrench counter-clockwise to clear chips and debris from the hole.

Step 6: Clean the Newly Tapped Hole

Once the new thread has been tapped, use a clean rag and brake cleaner or acetone to clean any remaining debris and cutting oil from the hole.

Step 7: Install the Thread Insert

Following the instructions provided in the thread repair kit, install the thread insert onto the insertion tool. Apply cutting oil or lubricant to the thread insert to facilitate smooth installation. Carefully insert the thread insert into the newly tapped hole, turning the insertion tool clockwise. Ensure the insert remains straight and aligned with the hole during installation.

Step 8: Break Off the Tang (If Applicable)

Some thread repair kits, such as Heli-Coil, have a tang at the bottom of the insert that needs to be removed after installation. To break off the tang, use a flathead screwdriver or the provided tool in the kit to apply pressure to the tang until it snaps off.

Step 9: Check the Insert’s Position

Ensure that the installed thread insert is flush with the engine block’s surface or slightly below it. This will ensure proper bolt seating and prevent potential damage to the engine block or the bolt.

Step 10: Install the Bolt

With the thread insert installed, you can now insert the bolt into the repaired hole. Tighten the bolt by hand first to ensure proper thread engagement. Then, use a torque wrench to tighten the bolt to the manufacturer’s recommended torque specification.

By following these steps, you can effectively repair a stripped bolt hole in an engine block, restoring the functionality and integrity of the engine. Patience and attention to detail are essential to achieve a successful repair, as rushing through the process or using improper techniques can lead to further damage or an unsatisfactory result. With the proper tools, materials, and techniques, you can fix a stripped bolt hole and keep your engine block in good working condition for years to come.

Step 11: Test the Repair

Once the bolt has been properly installed and torqued, start the engine and check for any signs of leaks or other issues around the repaired bolt hole. If there are no issues, the repair can be considered successful.

Step 12: Reassemble the Engine (If Applicable)

If you had to disassemble any parts of the engine to access the stripped bolt hole, carefully reassemble those components following the manufacturer’s guidelines. Ensure that all connections, hoses, and fasteners are properly installed and tightened to the correct torque specifications.

Step 13: Regular Maintenance and Inspection

To prevent future issues with stripped bolt holes, regularly inspect and maintain your engine, tightening bolts to their proper torque specifications as needed. This will help ensure the longevity and optimal performance of your engine.

By following these steps, you can effectively repair a stripped bolt hole in an engine block and restore its functionality and integrity. Remember that patience and attention to detail are key to a successful repair, as rushing through the process or using improper techniques can lead to further damage or an unsatisfactory result. With the proper tools, materials, and techniques, you can maintain your engine’s performance and extend its lifespan for years to come.

How to Identify a Stripped Bolt Hole in Engine Block?

A stripped bolt hole in an engine block is a common problem during engine repairs. A few telltale signs indicate a stripped bolt hole, and it is important to be able to identify these signs so that the problem can be fixed correctly.

Some of the most common indicators of a stripped bolt hole are when the bolt will not thread into the hole, or when the bolt becomes very difficult to remove after being installed. In addition, stripped bolt holes often have damaged or misshapen threads.

If any of these signs are present, a stripped bolt hole is likely present, and the engine block will need to be repaired before the engine can be reassembled.

Tips and Tricks for Avoiding or Fixing a Stripped Bolt Hole in Engine Block

There are a few tips and tricks that come in handy when it comes to avoiding or fixing a stripped bolt hole in an engine block.

The first is to use a slightly larger bolt than the original. This will give you a little extra room to work with and will help to avoid stripping the hole further. If the hole is already stripped, you can try using a threaded insert. This is a small metal sleeve that goes over the stripped thread, essentially giving the bolt something to grip onto.

If all else fails, you can always drill out the stripped hole and start from scratch. This may seem like a lot of work, but it’s a quick and easy fix. With a little patience and some know-how, you can have your engine block back in working order! If you want to know more about how to fix a stripped bolt hole in an engine block, keep reading.

How to Tell If You Have a Stripped Bolt Hole in Your Engine Block

One of the most common ways a stripped bolt hole can occur in an engine block is cross-threading. This happens when the bolt is not inserted perfectly straight, but instead at an angle. This can damage the threads and eventually strip out the hole.

Another way this can happen is if there is already damage to the threads from a previous repair. If the hole is not tapped properly, it can also cause the threads to strip out. There are a few ways to tell if you have a stripped bolt hole in your engine block.

There are three main indications that a hole is stripped: if a bolt seems stuck when you try to remove it, if the threads are damaged or missing when you look at the hole, or if a bolt will not go all the way in or seems cross-threaded when you try to insert it.

How Do You Helicoil an Engine Block?

Every car owner will need to perform some basic maintenance on their vehicle at some point. This may include changing the oil, checking the tires, or helicoiling an engine block.

While the first two tasks are relatively straightforward, helicoiling an engine block can be more challenging. However, with a few simple tools and patience, even a novice can complete this repair.

The first step is to remove the damaged threads from the engine block. This can be done with a tap and die set or by using a thread chaser. Once the damaged threads have been removed, clean out any debris or metal filings that may be present.

Next, apply some thread locker to the new Helicoil insert and screw it. Finally, reinstall the bolt or stud used to secure the repair.

Frequently Asked Question

Can You Fix a Stripped Bolt Hole?

The answer is yes. If you have a stripped bolt hole in your engine block, you must fix it as soon as possible. A stripped bolt hole can cause serious damage to your engine and may even require a rebuild.

Will Loctite Work on Stripped Threads?

Yes, Loctite will work on stripped threads. It is a good idea to use Loctite when repairing stripped bolt holes, as it will help keep the bolt in place and prevent it from coming loose again.

Conclusion

So there you have it. A step-by-step guide on how to fix a stripped bolt hole in engine block. We hope this article was helpful and that you can now fix the issue yourself without having to take your car into the shop. Have any questions or comments? Let us know in the comment section below!

You May Also Read: How to Fix Stripped Faucet Threads