Are you having trouble with your resin casting? Are the parts you try to cast coming out yellow instead of their desired color? If so, don’t worry! You can fix this issue pretty easily. Today’s post discusses how to fix yellow resin and get your casting process back on track. Keep reading to learn more!

Summary: Yellow resin is a common issue with 3D printers and can be caused by several different factors. The most common cause of yellow resin is exposure to too much light, which causes the resin to degrade.

To fix yellow resin, start by ensuring the printer has adequate ventilation and is not exposed to direct sunlight or bright lights. Make sure the seal around the tank is tight fitting and check the gaskets for any wear or damage. Additionally, resins that are low in photoinitiators can help prevent yellowing due to overexposure to light.

What Causes Yellow Resin?

There are a few different things that can cause your resin to turn yellow. The most common culprit is overexposure to UV light. Resin is a photopolymer, which means that it cures (hardens) when exposed to UV light.

Therefore, if your resin is exposed to too much UV light, it will cure too quickly, and this can cause the color to change. Another possible cause of yellow resin is contamination. If your resin is contaminated with oils or other foreign substances, it can also cause the color to change.

Additionally, some resins are more prone to yellowing than others. If you’re having trouble with yellowing, a different resin formulation might be worth trying. The other thing to remember is that not all resins are created equal. Some resins are more prone to yellowing than others. Again, a different resin formulation might be worth trying if you’re having trouble with yellowing.

Why Is Yellow Resin Bad?

Yellow resin isn’t necessarily “bad,” but it can be undesirable for certain applications. For example, if you’re trying to cast a clear part, you definitely don’t want it to come out yellow! Additionally, some people prefer the look of white or clear resin over yellow resin.

Another reason yellow resin can be bad is that it can indicate a bigger problem. For example, if your resin is turning yellow due to overexposure to UV light, your curing process is too fast and can cause parts to warp or deform. Finally, if your resin is contaminated, this can affect the strength and durability of your final parts.

Some Effective Ways How to Fix Yellow Resin

1. Use a Different Resin Formulation

If you’re having trouble with yellowing, a different resin formulation might be worth trying. Some resins are more prone to yellowing than others. Try doing a bit of research to find a resin that is less likely to yellow.

If you’re unsure where to start, ask for recommendations from other resin users or reach out to a resin manufacturer. Try to find a resin that is specifically designed for clear casting. Avoid using general-purpose resins or resins that are not intended for casting.

2. Clean Your Resin

If your resin is contaminated, this can affect the color. To clean your resin, start by removing any obvious contaminants, such as dust or debris. Then, try washing your resin with soap and water. You can also use isopropyl alcohol to clean your resin. If you’re still having trouble, you can try using a commercial resin cleaner. Avoid using harsh chemicals or solvents to clean your resin, as this can damage it.

3. Cure Your Resin in a Dark Place

Make sure you’re curing your resin in a dark place. UV light can cause yellowing, so avoiding exposure during the curing process is important. You can cure your resin inside a box or under a UV-blocking film. If you’re using a UV lamp to cure your resin, ensure it is properly shielded. If you’re not sure, err on the side of caution and cure your resin in a dark place.

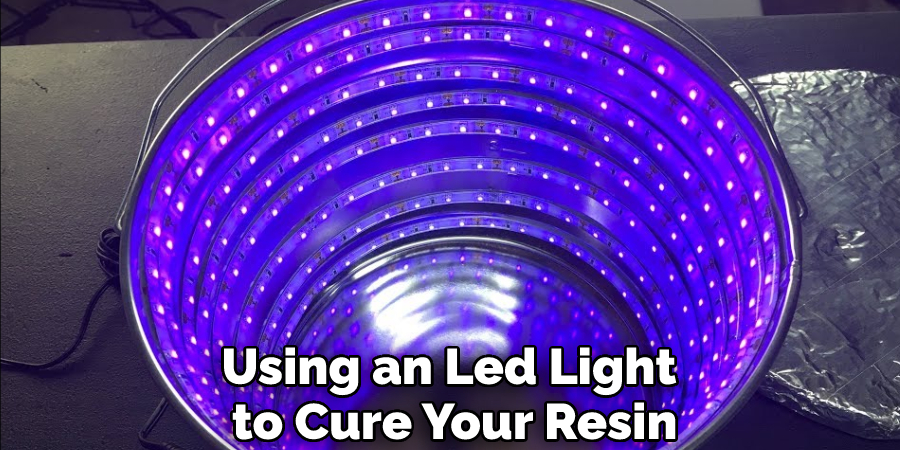

4. Use a Different UV Light

If you’re using a UV lamp to cure your resin, try using a different light. Some lights are better than others. If you’re using a CFL bulb, switch to an LED lamp. If you’re using an LED light, try moving it closer to your piece or curing it for a longer time. Avoid using sunlight to cure your resin, as it can cause yellowing. If you live in a sunny climate, try using an indoor curing lamp.

5. Reduce Your Exposure Time

If you’re curing your resin for too long, this can cause yellowing. Try reducing your exposure time and see if this helps. Try different resin brands, as some are more prone to yellowing than others. If you’re using an LED light to cure your resin, try moving it closer to the surface of the resin. This will help the curing process and reduce the overall exposure time.

6. Cover Your UV Light

If you’re using a UV lamp to cure your resin, ensure it is properly shielded. Some lamps come with a cover that helps to reduce the risk of yellowing, but you can also make your own cover with aluminum foil. Make sure the foil is tightly wrapped around the lamp and that there are no gaps. If you can see any light leaking through, the risk of yellowing is increased. You should also avoid using your UV lamp for extended periods. Try to cure your resin in short bursts, no more than 30 minutes at a time

7. Use a Lower Temperature

If you’re curing your resin at a high temperature, this can cause yellowing. Try reducing the temperature of your curing area and see if this fixes the issue. The ideal temperature for curing resin is between 70-80 degrees Fahrenheit. If you’re curing in an oven, set it to the lowest possible temperature.

8. Use a Dehumidifier

If the air in your curing area is too humid, this can cause yellowing. Try using a dehumidifier to reduce the humidity and see if this helps to clear up the yellowing. If you don’t have a dehumidifier, you can try running a fan in the room to circulate the air and help reduce the humidity. Avoid using a hair dryer, as this can increase the air’s humidity and make the yellowing worse.

9. Use a White Pigment

If you want to avoid yellowing, you can try using a white pigment in your resin. This will help to reflect the UV light and reduce the amount of yellowing that occurs. You can find white pigments at most craft stores. To use them, first mix the pigment with a little bit of alcohol. Then, add it to your resin and mix it well. If you add too much pigment, your resin will be opaque. So, start with a small amount and add more if needed.

10. Avoid Overheating Your Resin

If you heat your resin too much, this can cause yellowing. Avoid using hot water or placing your mixing container in direct sunlight when mixing your resin. If you need to speed up the curing process, use a hair dryer on a low setting or a heat lamp placed several inches away from your work surface. Try to keep the temperature of your resin below 100°F (38°C).

Tips and Warnings on How to Fix Yellow Resin

Tips:

- Be sure to use a UV-blocking film when curing your resin.

- If your resin is still tacky, try increasing the curing time or using a stronger light source.

- If your resin has cured yellow, you can try bleaching it with hydrogen peroxide.

- Try storing your resin in a cool, dark place to prevent it from yellowing.

- If all else fails, you can try painting over your yellow resin with white paint.

Warnings:

- Wear gloves and eye protection when working with resin.

- Be careful not to get any on your skin or clothes.

- Work in a well-ventilated area.

- Dispose of resin properly when you’re finished with it.

- Do not eat or drink while working with resin.

Can You Use Resin if It Turns Yellow?

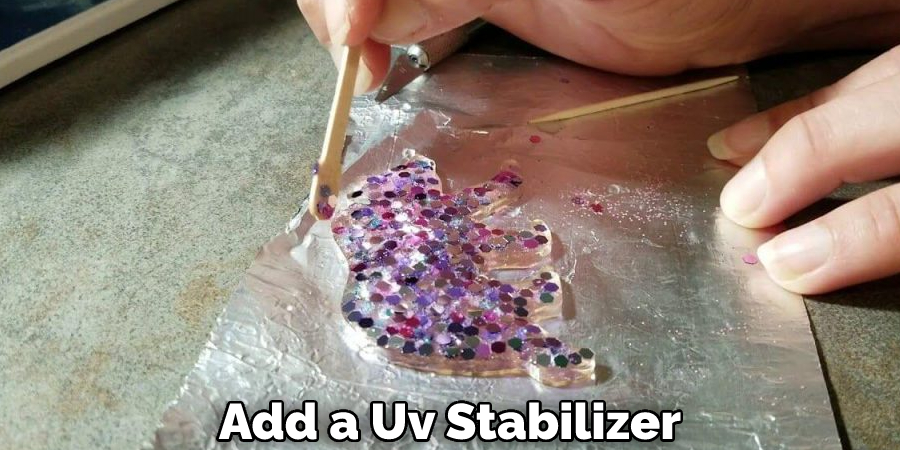

If your resin turns yellow, it is still usable. However, it may not cure properly or may not be as strong as it would be if it were a different color. You can try fixing yellow resin by adding a UV stabilizer or storing it in a cool, dark place. If your resin is still yellow after trying these things, it’s probably best to start over with a new resin.

What Is the Best Way to Fix Yellow Resin?

The best way to fix yellow resin is to add a UV stabilizer. This will help protect your resin from the sun and other UV light sources. You can also try storing your resin in a cool, dark place. This will help prevent it from turning yellow. If your resin is still yellow after trying these things, it’s probably best to start over with a new resin.

Frequently Asked Questions

Why Has My Resin Gone Yellow?

If you’ve noticed your resin going yellow over time, there may be a few potential causes. The most common reason is that the resin has become oxidized and this can happen due to environmental factors like sunlight or smoke exposure. It can also occur as a result of improper storage or smoking practices.

Other reasons for the color change include using low-quality marijuana, using too much water when processing the cannabis, and using an acidic solvent such as vinegar instead of HCL (hydrochloric acid). In order to prevent oxidation from happening and ensure correct resin production, it is important to follow these guidelines: avoid exposing your cannabis to direct sunlight; use fresh water rather than tap water; avoid excessive moisture in the air; use clean equipment, and take care not to contaminate your work area with residual solvents.

Can You Clean Yellowed Resin?

Resin can be difficult to clean, but there are a few methods that you can try. One option is to use a vinegar and water mixture, which will help remove any stains or debris. Another option is using dilute soap solutions (1/4 cup of liquid soap per gallon of water) or Oxy-Clean® Max Bleach Solution with Microban®, both of which are effective at removing dirt, polish, food residue, and other staining agents.

If neither of these techniques works satisfactorily for you, then it may be necessary to call in the professionals! A non-toxic cleaner such as Envirocare’s Professional Grade Resin Cleaner Kit may be the answer for tougher jobs. This product has been specifically designed to clean resin without damaging its surface finish.

Does All Resin Yellow Over Time?

the condition of your resin will vary depending on a number of factors, including the amount of light exposure it receives, the type of resin, and the environmental conditions. That being said, most resins will eventually yellow over time due to exposure to sunlight or other forms of light. This process can be accelerated by the use of certain chemicals or solvents, which can cause the resin to crystallize and turn yellow.

What Epoxy Does Not Turn Yellow?

Epoxy does not turn yellow over time. Epoxy is a type of glue that forms a strong seal when it comes to joining two surfaces together. It can be used for a variety of purposes, such as installing flooring and cabinets, repairing broken windows or tiles, or attaching furniture to walls.

Because epoxy is an adhesive, it will gradually bond with any surface it comes in contact with. This means that if you happen to spill epoxy on the floor, ceiling, or other areas where it would come into contact with the skin, your clothing/skin will also start turning yellow over time.

To avoid this problem, make sure to wear gloves while working with epoxy and keep direct exposure to its liquid form limited as much as possible. Additionally, try coating the affected area (e.g.

Conclusion

So there you have it! These are some tips on how to fix yellow resin. Follow these tips, and you should be able to get your resin back to its original color. We hope you found this article helpful. If you have any other questions or comments, please feel free to leave them below. Thanks for reading!