A hydraulic hood lift is an automotive lifting device that uses hydraulics to raise and lower a vehicle’s hood. Hood lifts are commonly used in garages and auto body shops to allow mechanics to access the engine compartment for maintenance and repairs easily. Hydraulic hood lifts can also be used to show off the engine simply by raising the hood while the vehicle is on display.

Has your hydraulic hood lift stopped working properly? Don’t worry, and you’re not alone. Many people have this problem, and it can be fixed fairly easily. In this blog post, we will walk you through the steps to diagnose and how to fix hydraulic hood lift. Remember that while these instructions are specific to hydraulic hood lifts, they can be generally applied to any car repair. So read on, and get started fixing your car!

Summary: In this blog post, we’ll give you the steps you need to take in order to fix it. We’ll cover topics such as gathering your tools and opening the hood, as well as checking the fluid level and looking for leaks.

Additionally, we’ll discuss how to bleed the system, clean the filters, check the hoses, check the battery, lubricate the pins and test the system. Finally, if necessary, we’ll outline how to replace the lift so that your hydraulic hood lift is functioning properly.

What Causes a Hydraulic Hood Lift to Stop Working?

There are a few different things that can cause a hydraulic hood lift to stop working. The most common issue is that the hydraulic fluid has become dirty or low and needs to be replaced. Another possibility is that there is an air bubble in the system, which can happen if the system is not bled correctly. Additionally, a leak in the system can cause the hydraulic fluid to escape, resulting in the lift not working properly.

The other possibility is that the lift itself is just damaged or worn out and needs to be replaced. Lastly, if the battery is dead, that can also prevent the hydraulic system from working.

Is it Safe to Drive with a Broken Hydraulic Hood Lift?

If your hydraulic hood lift is not working, driving your vehicle is unsafe. This is because the hood could come up while you are driving and block your view of the road. Additionally, suppose the hood is not properly secured. In that case, it could come off entirely while you are driving and cause serious damage to your vehicle or injure other people on the road. For these reasons, fixing your hydraulic hood lift before driving your car is essential.

Another reason not to drive with a broken hydraulic hood lift is that your engine could overheat. If the hood is up, the engine will overheat much faster than usual because it cannot dissipate the heat properly. For this reason, fixing your hydraulic hood lift before driving your car is essential to prevent your engine from overheating.

Step by Step How to Fix Hydraulic Hood Lift

1. Gather Your Tools

The first step is to gather the tools you will need to fix your hydraulic hood lift. You will need a new bottle of hydraulic fluid, a funnel, a clean cloth, and a wrench set. Gather these tools and put them in a safe place where you can easily access them. If you do not have a wrench set, you can borrow one from a friend or neighbor.

2. Open the Hood

The next step is to open the hood of your car. First, locate the hydraulic hood lift release handle. This is usually located near the engine compartment. Once you have found the handle, pull it to release the hood. You may need to use the manual release handle if the hood does not open. This is usually located inside the car near the driver’s seat.

3. Check the Fluid Level

Once the hood is open, locate the hydraulic fluid reservoir. This is usually a clear plastic container with a screw-on lid. Remove the lid and check the fluid level. If the fluid is low, add more until it reaches the full line. First, pour the new fluid into a clean container. Then, use the funnel to pour the fluid into the reservoir. Be sure not to overfill the reservoir.

4. Check for Leaks

The next step is to check the hydraulic system for leaks. First, look for any wet spots on the ground beneath the car. If you see any, that is an indication of a leak. Another way to check for leaks is to look at the hydraulic fluid reservoir. If the fluid level is lower than it should be, that indicates a leak. If you find any leaks, you will need to repair them before proceeding.

5. Bleed the System

The lift will not work properly if there is an air bubble in the hydraulic system. To remove the air bubble, you will need to bleed the system. First, locate the bleeder valve. This is usually a small knob or lever located near the hydraulic fluid reservoir. Once you have found the bleeder valve, turn it counterclockwise to open it. Then, have a friend pump the hydraulic handle while you hold the valve open.

Once the fluid starts to flow out of the valve, close it and have your friend stop pumping. Check the fluid level in the reservoir and add more if necessary.

6. Clean the Filters

If the filters are dirty, they can cause the hydraulic system to malfunction. To clean the filters, first, locate them. They are usually located near the hydraulic fluid reservoir. Once you have found the filters, please remove them and rinse them with clean water. Then, dry them off and put them back in place. If the filters are damaged, you will need to replace them.

7. Check the Hoses

If the hoses are damaged, they can cause the hydraulic system to malfunction. To check the hoses, first, locate the reservoir. It should be close to the engine and have a clear lid to see the fluid level. Once you’ve found the reservoir, follow the hoses to see if they are damaged. If you see any cracks or leaks, the hoses will need to be replaced.

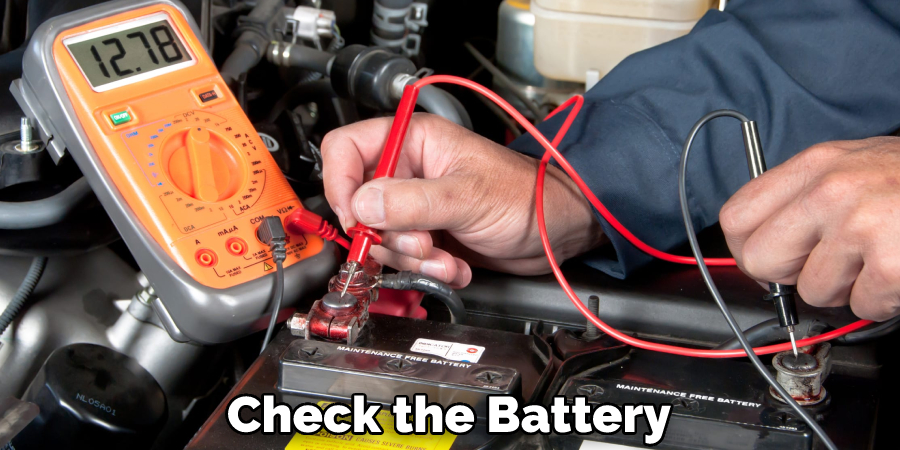

8. Check The Battery

If the battery is weak, it may not have enough power to operate the hydraulic system. To check the battery, first, make sure that it is properly charged. If the battery is low, try charging it or replacing it with a new one. Next, test the battery by starting the engine and opening the hood. If the engine stalls or the hood does not open, the battery may be the problem.

9. Lubricate The Pins

If the pins that connect the hydraulic system to the hood are not properly lubricated, the system will not work properly. To lubricate the pins, first, remove the pin covers. These are usually small plastic caps that can be pried off with a screwdriver. Once the covers are off, apply a light coat of lubricant to the pins. Be sure not to use too much, or the lubricant will drip onto other parts of the car.

10. Test The System

Once you have completed all of the previous steps, it is time to test the hydraulic system. First, open the hood and locate the hydraulic fluid reservoir. Then, fill the reservoir with hydraulic fluid. Next, turn on the engine and open the hood. If the system is working properly, the hood should stay open. If the hood does not stay open, check the fluid level and add more if necessary. Finally, close the hood and check for leaks. If you see any, repair them and test the system again.

11. Replace The Lift If Necessary

If the hydraulic system is not working properly, you may need to replace the lift. This is because the problem may be with the pump, which is not easily accessible. You can purchase a new lift from various sources, including auto parts stores and online retailers. Make sure to get the right model for your vehicle. To do this, first, disconnect the battery. Next, remove the old lift by disconnecting the hydraulic lines and removing the bolts that hold it in place.

Finally, install the new lift and reconnect the hydraulic lines. If you are not sure how to do this, consult your vehicle’s owner’s manual or a professional mechanic.

You Can Check It Out To Fix Engine Lifter Noise

Tips and Warnings on How to Fix Hydraulic Hood Lift

Tips:

- Be sure to read your car’s owner’s manual before attempting to fix your hydraulic hood lift. This will give you important information on the location of the parts and how they work together.

- If you are not confident in your ability to fix the problem, it is best to take your car to a mechanic or other expert.

- Always use caution when working with hydraulic fluids, as they can be dangerous.

- Be sure to have all the necessary parts and tools before beginning the repair.

Warnings:

- Do not work on a car while it is running.

- Do not work on a car that has been turned off for less than two minutes.

- Wear safety glasses when working on a car.

- Do not use power tools when working on a car.

- Do not use your hands to feel for leaks. Use a rag soaked in soapy water.

Frequently Asked Questions

What is the Thing That Holds Up the Hood Called?

The hood of a car is often referred to as the “thing that holds up the hood.” This name comes from its traditional function of protecting drivers and passengers from the elements. It can also be used figuratively to describe anything that keeps something hidden or secret.

Why Won’t My Gas Struts Compress?

If you are experiencing a problem with your gas struts not compressing, there could be a few reasons for this. First, it is possible that your struts are defective and need to be replaced. Second, it’s possible that your gas system is not receiving the correct amount of fuel. Third, it could be that your gas system is clogged up and needs to be cleaned. In any case, if you experience problems with your gas struts not compressing, it is important to take action and rectify the issue as soon as possible.

Should I Be Able to Compress a Strut by Hand?

When it comes to strutting compression, the answer is yes and no. While manual strut compression can be helpful in some cases, it is not typically recommended for everyday use. Instead, professionals typically recommend using a specialized tool called a strut compressor.

Austrian’s Strut Compressor has been designed specifically for this purpose and features adjustable dual pistons that compress the strut without damaging it. It also has an ergonomic design that makes it easy to operate and reduces arm fatigue over time. In addition, Austrian offers a lifetime warranty on its compressor so you can feel confident in your purchase decision.

Conclusion

So there you have everything you need to know on how to fix hydraulic hood lift. Be sure to follow the steps carefully and take your time so that you do not make any mistakes. With these tips, you should be able to fix your hydraulic hood lift in no time. Thanks for reading!